Blow through valves - RO-BO Mechanical Workshop

Main menu

- Home Page

- Company

- Contacts Mail

- Coffee Grinder RW-70

-

Valves EN 15089

- Rotary valves EN 15089

- Main features

- Products

- Explosion barrier

- Images

- Certifications

- Valves TN/TS

- Valves TNA/TNAS

- Valves VP/VPC

- Atex valves

- Rotary valves

- Blow Through valves

- Food Indusry

- Diverting valves

- Rotary valves for microdispensing

- Interception valves

- Gearbox

- Spare parts - Works for third parties

- Collaborations

-

Restricted area

- Registration form

- Customers

- Service

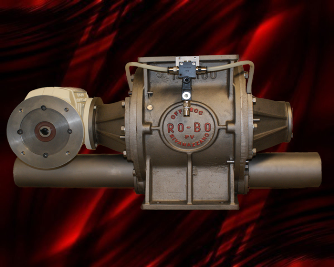

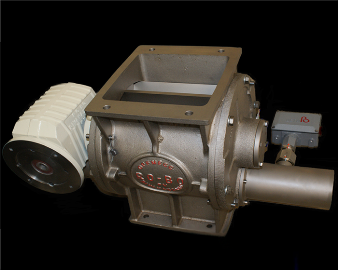

Blow through valves

BLOW THROUGH VALVES

Blow-

Robust, powerful and economical, the airlocks TN – TS – TNA – TNAS are an extremely valid solution: the robust design and precision workmanship improve operating reliability and reduce running costs. In the version certified EN 15089 also constitute an insurmountable BIDIRECTIONAL barrier against explosion.

Broad application range – The range of materials suitable for conveyance is extremely varied: it begins with normal grinding materials and goes on to include abrasive and corrosive materials, sugars, resinoids, gluing. The ability to transport materials at high temperatures increases the unit's flexibility: our blow-

An ingenious design of the system AIRLOCK saves energy. Due to our exclusive configuration, the unit is able to effectively reduce the energy consumption and the coupling with our gear allows to obtain a very high efficiency degree with a negligible noise.

The small clearance between the housing and rotor guarantee minimum air leakage. Sealing is ensured by the fact that, during operation, the rotors have always SEVEN / EIGHT plates in closing function.

The accurate and innovative project guarantees an optimum discharge, an excellent level of sanitation and PRESSURE DROPS, EMPLOYEES FROM THE VALVE, ALMOST VOID.

This assumption applies to the transport of all approved materials and for all plants, provided these last are properly designed, comply with the current rules and that their components are harmonized with the characteristics of the valve.

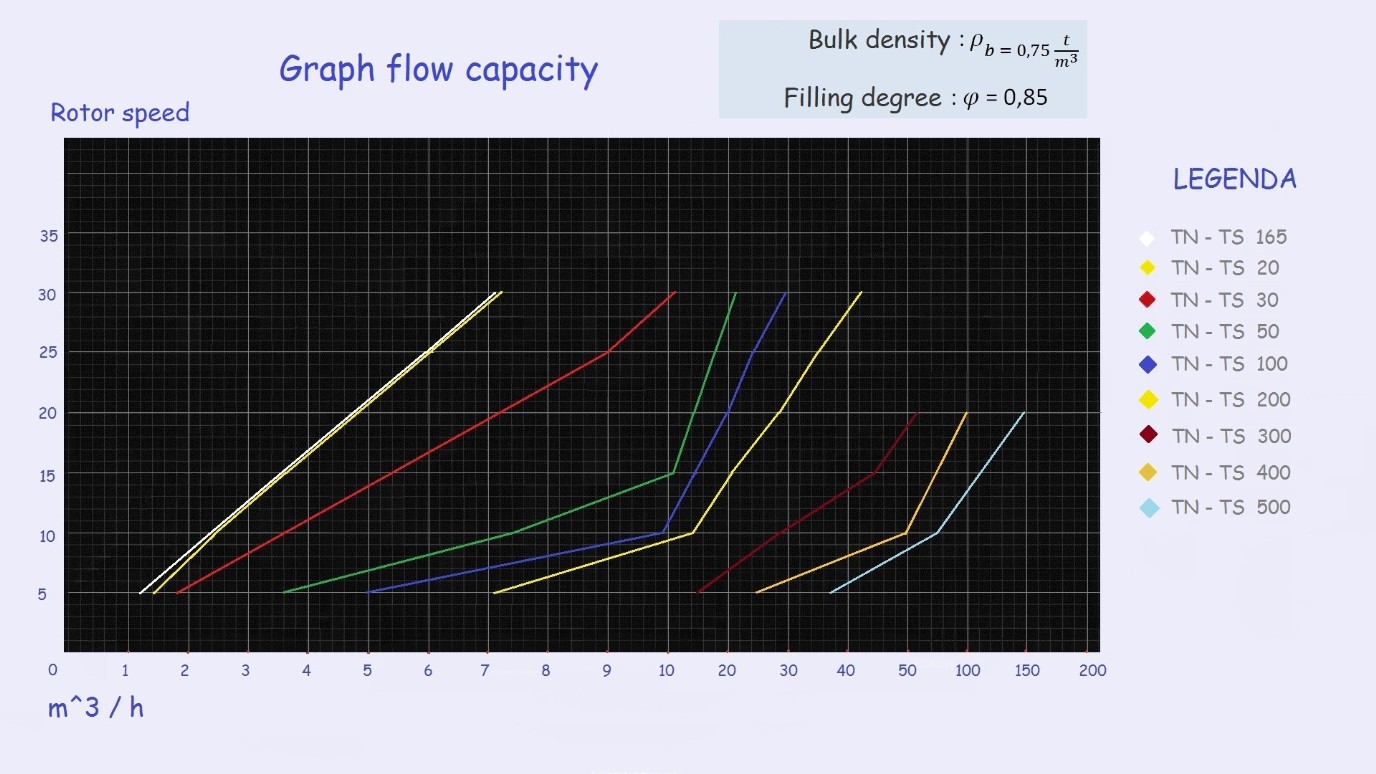

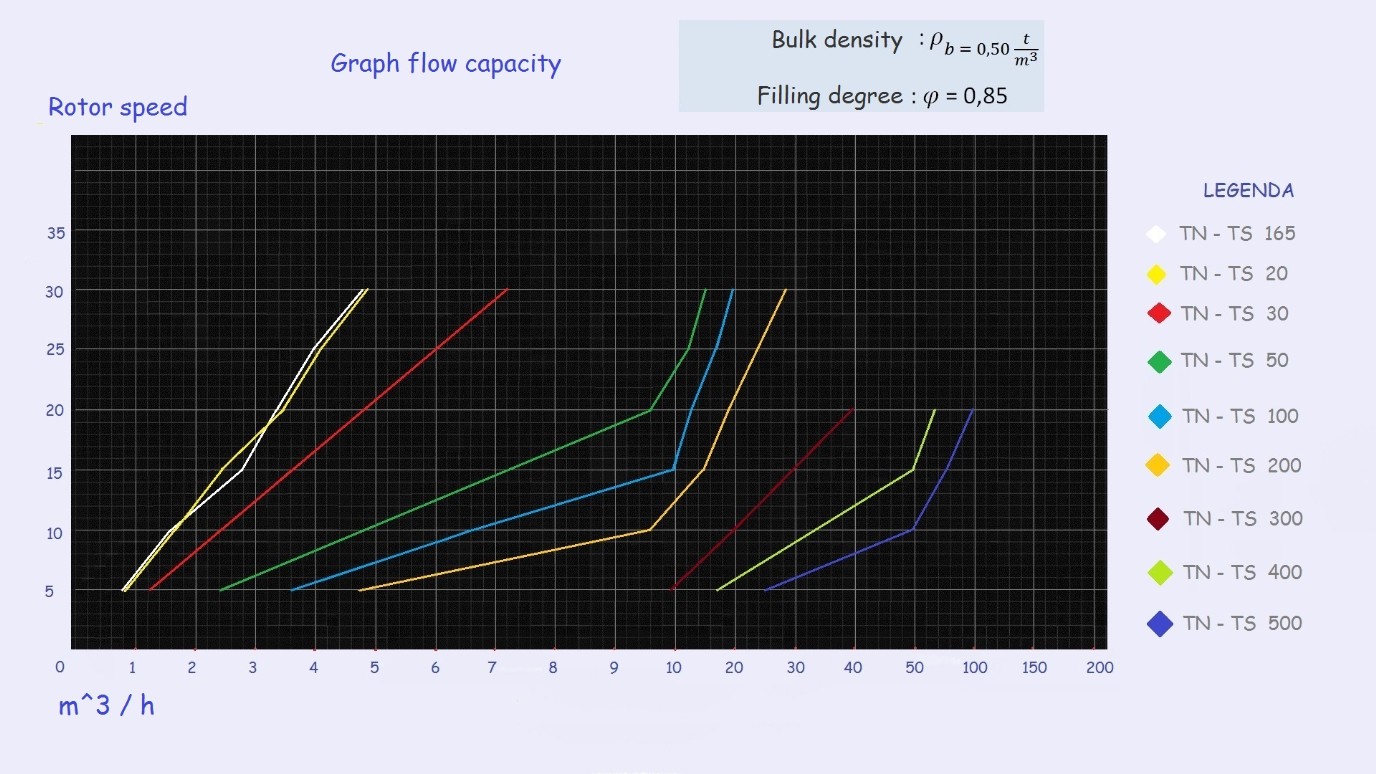

The throughput capacity of an airlock depends on the one hand on the properties of the product handled and its bulk density ρ_b, and on the other hand on the airlock geometry, its rotor speed and the pressure differential existing in the conveying system. This gives the volume and the filling degree φ .